| |

Rapid

Prototyping

Rapid prototyping or 3D printing has been a very important stage of mould tool design for the past ten years, it gives designers project managers and anyone involved in the design of a part that is going to be molded the opportunity to handle their product, assemble it or even do some functional testing prior to finalizing the design and ordering some very valuable tooling.

There are several rapid prototype systems currently available including SLS (Selective Laser Sintering), SLA (Stereo Lithography), FDM (Fused Deposition Modeling), PolyJet & SRP (Subtractive Rapid Prototyping).Red Arete's prototype bureau uses FDM producing ABS models and SRP, with a selection of materials, from your CAD data and shipping the part to you

in a matter of days. This technology can reduce your 'time to

market' dramatically, by providing a part that can be assembled or

used in pre-production trials weeks before the real parts

would normally be ready. With a new new materials & expanded service for 2012 we are confident we'll get you the most competitive prototype price in the UK.

Call 07957 249 043 or e-mail Ian@red-arete.co.uk for a prototype quote.

|

|

| |

FDM rapid prototyping is a method of printing a 3D part model by extruding an ABS filament to create a 2D shape as a layer. Layers are built on top of each other

to make a model, the model shape is defined by the STL file that controls the shape of each layer, most 3D CAD software systems

support STL data exchange.

The 3D part is made from ABS but the machine also uses a soluble support material to allow the machine to create bridge features. This support structure is broken away and washed of to leave the ABS of the printed 3D model.

The ABS models are very tough and in some cases have been

used as a working part in pre-production trials. |

|

|

| Click to view prototype gallery |

|

|

| |

|

| |

|

|

|

| |

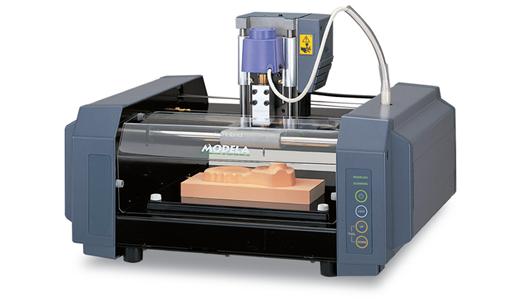

SRP is a method of machining a 3D part model from a solid block of material, this is essentially a small CNC milling machine using regular milling tools and produces a part almost identical to a production part. The parts can be machined on all sides as any normal milling operation. As per the FDM, the model shape is defined by the STL file that controls the shape of each layer, most 3D CAD software systems

support STL data exchange.

The 3D part can be made from a wide varity of materials from modelling foam & plastics to soft metals like aluminium & brass.

The models are very tough with an excellant tolerance and surface finish and since these models are machined from solid they will be as good as a production part. |

|

|

|

| |

|

| |

|

|

| |

| The rapid

prototype models are made from

ABS which can be easily treated to give

a smooth production part like surface which can even painted or chromed.

Parts can be bonded together with cyanoacrylate to

create even larger and more complex parts. |

|

|

| Dimension FDM

machine |

|

|

|

|

|

|

|

| |

Successful product design

requires review and input from many sources. FDM

3D models have proven time and time again to be great

marketing tools. ABS prototype models can be sanded, painted, and

chrome plated. Take a look at the wheel-loader to the

right. This model was printed in multiple pieces using

two colors. Imagine showing this quality model to a new

prospect. You are able to place a real-life product into

someone's hands in a day.

|

|

|

| Wheel-Loader |

|

|

|

|

|

|

| |

|

The benefits of this technology have been used by major

companies world wide to great effect:

- Functional testing with robust ABS models,

- Cost reduction and time compression,

- Parallel development of assembly tools or packaging.

- Better product development,

- Marketing and product mock ups,

- Vacuum forming moulds

- Medical models

- Sand casting patterns

|

|

|

| Vacuum forming |

|

|

|

|

|

|

| |

|

The costs of our FDM rapid prototype models are derived from the machine time, amount of material used and the amount of support material used to

produce the model. With less expensive materials we have been able to reduce the cost to clients.

So to give you an idea this typical coffee mug 100mm tall

and having a volume of around 180cm³ it would cost £150 and we

could have it in the post for you today!

Delivery of the parts is normally through Royal Mail's First Class, Special Delivery next day or Special Delivery 9am. This is normally included in the quote except for special circumstances. World wide delivery is an extra charge and does take a little longer , again we use the post office's services; international signed for & Airsure which can be very cost effective and reach its destination in less than 6 days. |

|

|

| Coffee Mug |

|

|

|

|